Printed Shrink Sleeves: What you need to know…

With head-turning graphics and vibrant colors, custom printed Shrink Sleeves offer some serious benefits:

- 360 degrees of amazing print.

- Wraps an entire bottle or container, up to 12 inches around.

- Moisture and abrasion resistance.

- Order minimum is only 250 Shrink Sleeves.

Our Shrink Sleeves are printed on an HP Indigo press. The digital image is laid down on a flexible film that reduces in size when it’s exposed to heat.

Shrink Sleeves are subsurface-printed for extreme durability.

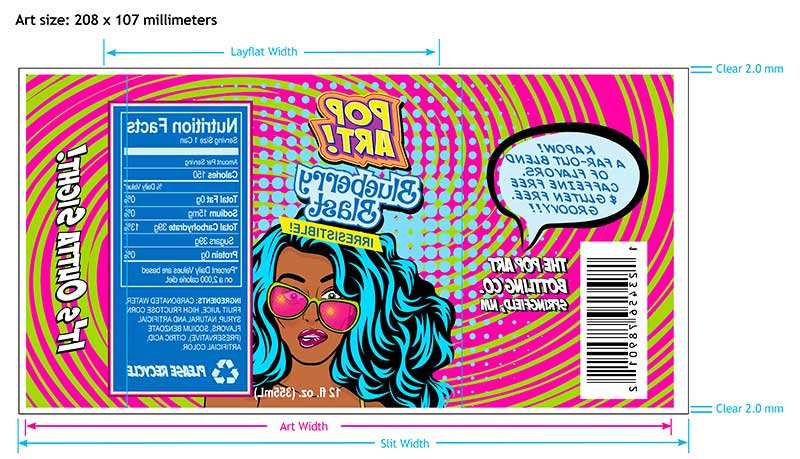

Shrink Sleeves are printed on the inside of plastic or polyester film material, so the print is protected. That’s why the Shrink Sleeve flat art in this catalog appears flipped. You’re seeing the artwork as it will print.

To ensure a sleeve will fit, you must provide a physical sampler or a manufacturer’s object (.obj) file of the container.

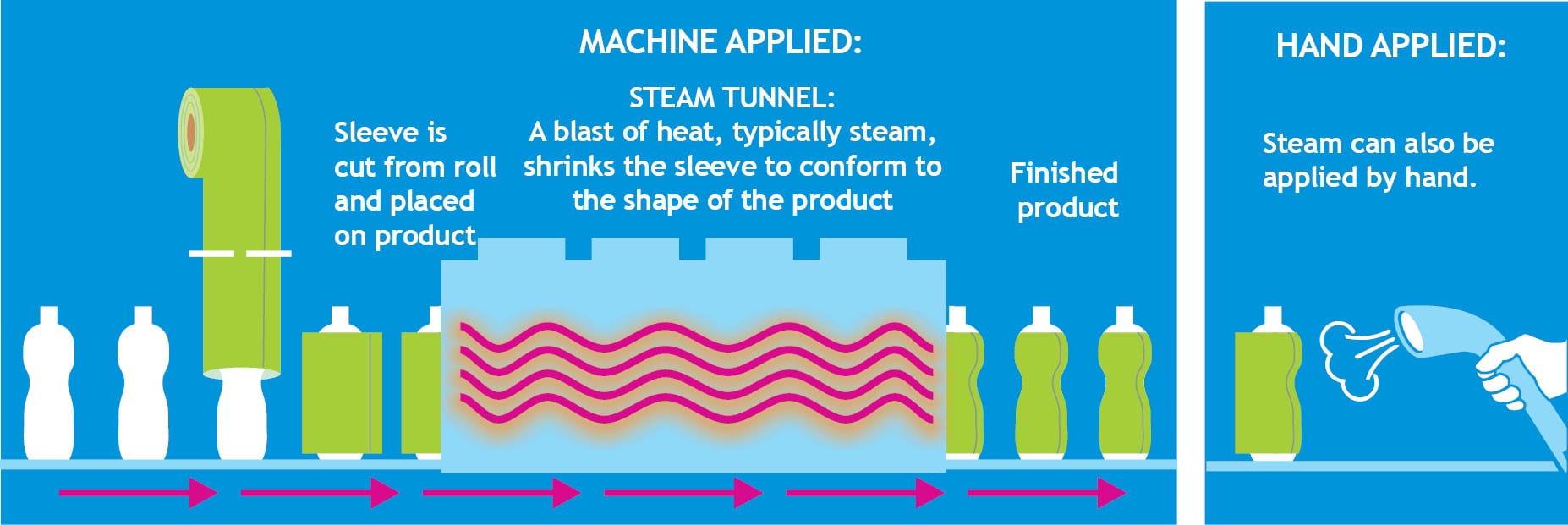

Shrink Sleeves are custom sized, down to the millimeter, to fit just about any container. Most often shrink sleeves are applied inline (at the bottling or packaging facility). They also can be hand applied.

The secret is heat, specifically STEAM. With a little heat, the sleeve conforms to the shape of the container on which it is placed. Steam is the most even heat, producing the smoothest application.